landrovereditor

Full Member

- Posts

- 23

- Likes

- 8

Looking through a lot of diagrams and threads on inverters, many just connect to the battery with no fuse or cut off switch.

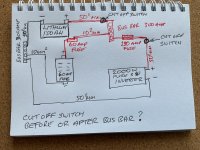

The diagram below is the one I propose to follow for wiring my inverter and fuse block to my battery.

The cut off switch is my stumbling block, do I put it between the inverter and the fuse or before the bus bar which obviously will cut off everything.

The inverter has an on off switch, the battery terminal is a quick release. Do I need the cut off? If so where to place it?

The diagram below is the one I propose to follow for wiring my inverter and fuse block to my battery.

The cut off switch is my stumbling block, do I put it between the inverter and the fuse or before the bus bar which obviously will cut off everything.

The inverter has an on off switch, the battery terminal is a quick release. Do I need the cut off? If so where to place it?